Introduction Finite Element Analysis

Finite Element Analysis (FEA) is a powerful numerical simulation tool used by engineers and designers to analyze and optimize their designs. It can be applied to a wide range of fields such as mechanics, thermodynamics, and structural engineering. With FEA, engineers can predict how a product will behave under different loads, temperatures, and other physical and environmental factors, making it an essential tool for modern engineering. FEA is widely used in the automotive, aerospace, biomedical, and construction industries, among others, to improve product design, increase reliability, and reduce the time and cost of physical testing. Best practices for using FEA include defining clear objectives, selecting appropriate modeling techniques, and verifying the accuracy of the results through validation and comparison with physical testing. FEA is a versatile and effective tool for engineering analysis and optimization, and it has proven to be an invaluable resource for many organizations.

CFD case studies

This research focuses on the nonlinear deformation and time-dependent interactions between stents with a self-recognition material (Shape Memory Alloy) and flexible vascular walls (Hyper-elastic tissue) under realistic conditions using a Finite Element method.

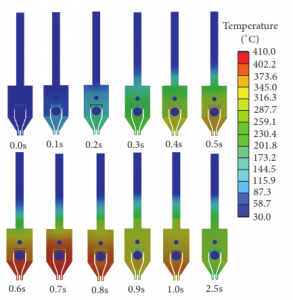

Welding tip is an appliance for assembling the small electronic part together had a problem. Sometimes it could not weld, or assembling parts got to burn.

We applied the thermal – electric simulation in finite element analysis, to solve The problem. The simulation results showed the heat transfer, heat flux, temperature, etc., in transient state. All results were analyzed to find the optimum design of the tip.

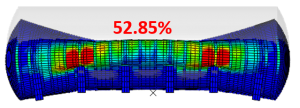

The cylindrical tank lies on 6 trapezoidal stands. In the case that all legs are completely supported on the ground, the filled tank is safe. If some stands are not supported evening on the ground, the filled tank can be broken and cause leakage of media, damage of surrounding properties, or even injury of a working person nearby.

Installation of a liquid storage tank on an unbalanced foundation may cause damage to the structure of the tank. This work will perform damage analysis by finite element technique (FE) of a horizontal composite tank with 6 supports subjected to live load capacity. The probability of foundation base may be installed unevenly from 1 to 4 supports.

The study has shown the damage opportunity due to the miss aligning installation. The results can be used as a precautionary measure to ensure that the foundation is leveled before installation to prevent any damage.

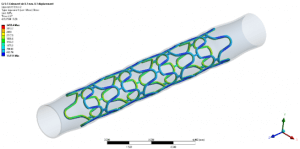

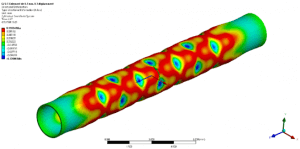

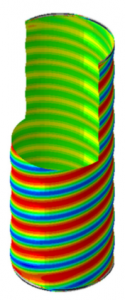

The unusual deformation response of the wavy thin cylinder, a helically corrugated cylinder, was studied using the finite element technique. The cylinder was loaded under the typical loading, i.e., Tension, Pressurized, and Torsional.

The unusual deformation induced by the wavy shells is sensitive to their configurations. It can be extraordinarily higher than the perfect round shell made of the same parent material. Unorthodox coupling quantities of torsional-axial, torsional-radial, and axial-radial coupling deformations are encountered at some specific geometries. The study has given a guideline to effectively design or select a proper helically corrugated cylindrical shell with the desired stiffness properties.

This project is ongoing in the experimental phase; the prototype was performed using additive manufacturing and composite material processing. The digital image correlation technique was developing to observe the physical response by the graphical technology.