Introduction Reactive flow

Reactive flows are flows that are chemically reactive. All types of fluid flows with chemical reactions occurring within the fluid phase, at the interphase between different fluid phases or at interphases to solids. Reactive flow finds its applications in many areas including catalytic cracking in chemicals process, combustion in IC engine, CO2 capture process, polymerization, etc. Simulation of reactive flows is becoming increasingly important because it allows researchers to gain insight into processes with difficult conditions, such as high temperature and pressure. In this way, the effort and costs for prototypes and field test can be reduced to a minimum.

CFD case studies

A gas-phase polypropylene polymerization fluidized bed is more attractive due to the fact that it can be operated with a high solid loading, requires neither drying nor separation of polymers from solvents and has relatively low environmental impact. Nevertheless, heat transfer in a gas-phase fluidized bed is limited, especially in a high-solid-loading mode of operation, due to highly exothermic polymerization and poor heat transfer in the gas phase of the system.

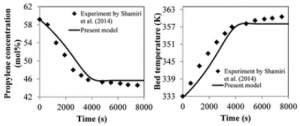

The goal of this project is to create models on two levels and show how useful they are for simulating a fluidized bed reactor for propylene polymerization. The operational variables investigated to improve productivity and change product attributes are catalyst feed rate, operating temperature, hydrogen feed, reactor size, and superficial velocity. Local distributions of phase movements and local temperature distributions will also be investigated in order to avoid polymer overheating, hot spots, and the possibility of melting. This research is unique and will contribute in the better understanding of propylene polymerization in fluidized bed reactors, as well as the examination of both a laboratory and an industrial reactor.

Contour of bed temperature for different reactor scales obtained using (a) Set I with weight space time similarity, and (b) Set II with hydrodynamic similarity

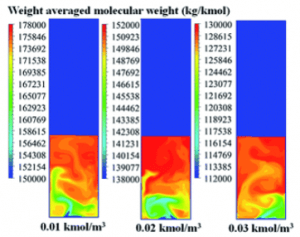

Contour of weight average molecular weight in the fluidized bed for various hydrogen feed concentrations