Introduction Turbo machinery

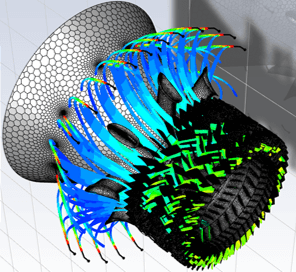

Turbines and compressors are examples of turbomachinery, which transfers energy between a rotor and a fluid. A compressor transfers energy from a rotor to a fluid, whereas a turbine transfers energy from a fluid to a rotor. Turbomachinery devices are found in many applications from different industries as fans, pumps, propellers, compressors and turbines. Regarding flow characteristics, it is convenient to make the distinction between low-Mach and high-Mach turbomachinery devices to understand the actual applications. Computational fluid dynamics (CFD) plays an essential role to analyze fluid flows and heat transfer situations.

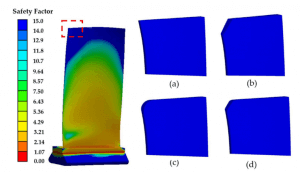

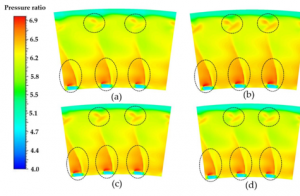

CFD case studies

This process uses ANSYS Fluent with RNG k-epsilon, droplet evaporation and wall-film modeling for consideration with limited multi-purpose optimization. To develop a design plan for selecting the optimal nozzle diameter, location, mass flow rate and full cone nozzle angle for Mitsubishi MW701D gas turbine power plant.